Categories

Contact

E-mail :

chiyuan@chiyuanmachine.com

Phone/Wechat:

+86-15100871888

Address:

Botou Economic Development Zone, Cangzhou City, Hebei Province, China

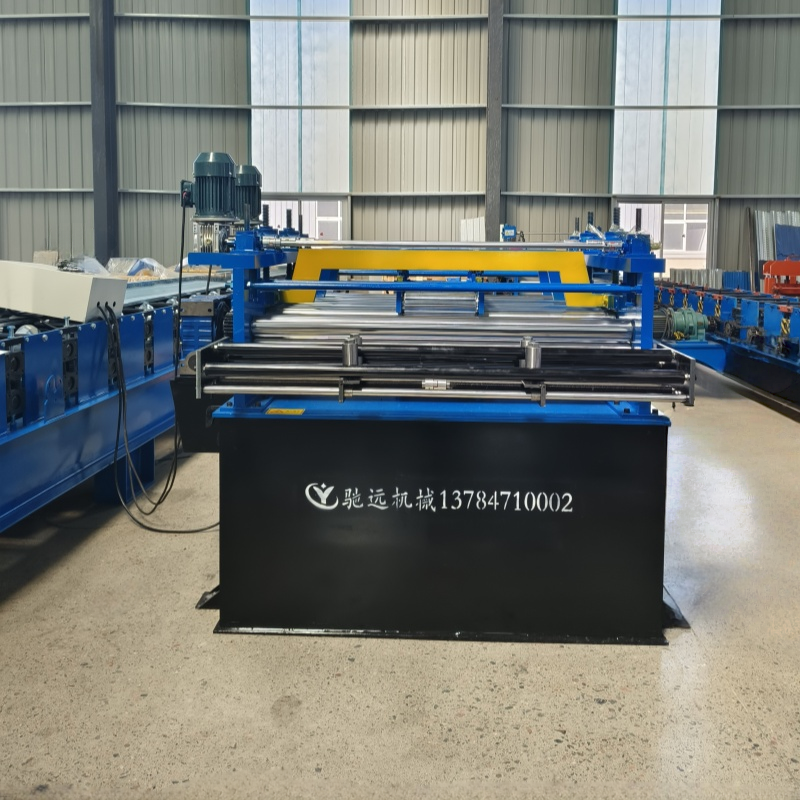

Leveling machine (leveling machine/leveling machine)

Metal material leveling machine, galvanized sheet, stainless steel sheet leveling equipment

The leveling machine is mainly used in the metal steel plate forming process, using the pressure of the upper and lower rollers to flatten uneven plates.

Applicable industries: Construction, building materials, manufacturing plants. Exhibition hall location: New. Condition: New. Material: Metal. Country of origin: China. Brand: Chi Yuan. Weight: 3600kg. Warranty period: 1 year. Automation level: Fully automated. Selling points: Simple operation, high safety performance, long service life, fully automatic rolling. Thickness: 0.3MM-1.2MM. Main equipment: Not specified. Width: 1300mm. Mechanical test report: Not specified. Factory inspection video: YES. Marketing type: Easy-to-operate and safe, hot-selling product. Core component warranty period: 1 year. Core components: Pump, motor, PLC, engine. Power: 5.5KW. Minimum order quantity: 1 set.

The leveling machine is mainly used for metal sheet forming and processing, flattening uneven plates by the pressure of upper and lower rolls to achieve a flat effect on the material.

An uncoiler unwinds tightly wound metal coils into a smooth, continuous strip, providing a foundation for subsequent processing. This ensures product quality and processing precision on the production line. A leveler is mainly used in metal sheet forming processing, using the pressure of upper and lower rollers to flatten uneven sheets.

Levelling shear machine is an important metal processing equipment, mainly used to improve the surface quality and dimensional accuracy of metal sheets, so that it can reach a higher processing standard.

Material leveling: By removing the uneven and raised part of the surface of the material, the surface is flat, which is particularly important for materials such as plates and metal sheets that need to be smooth.

Improve parallelism and verticality: The edge or surface of the material is compared and trimmed with the datum surface to improve the parallelism and verticality of the material, which is of great significance for products requiring high-precision machining.

Repair bent or deformed material: Used to repair already bent, deformed or uneven sheet, by applying moderate pressure and stretching to restore the flatness of the material.

Pretreatment material: Pretreat the supplied sheet metal, and adjust the parameters and operation of the flattening machine to provide a more flat and stable material for the subsequent cutting, stamping, welding and other processing operations

Semi-automatic leveling machine

Product name: Semi-automatic leveling machine

Semi-automatic leveling machine is mainly used for leveling various metal sheets to improve their flatness and surface quality. Its semi-automatic feature not only retains a certain degree of convenience in automated operation, but also gives the operator enough control and adjustment space.

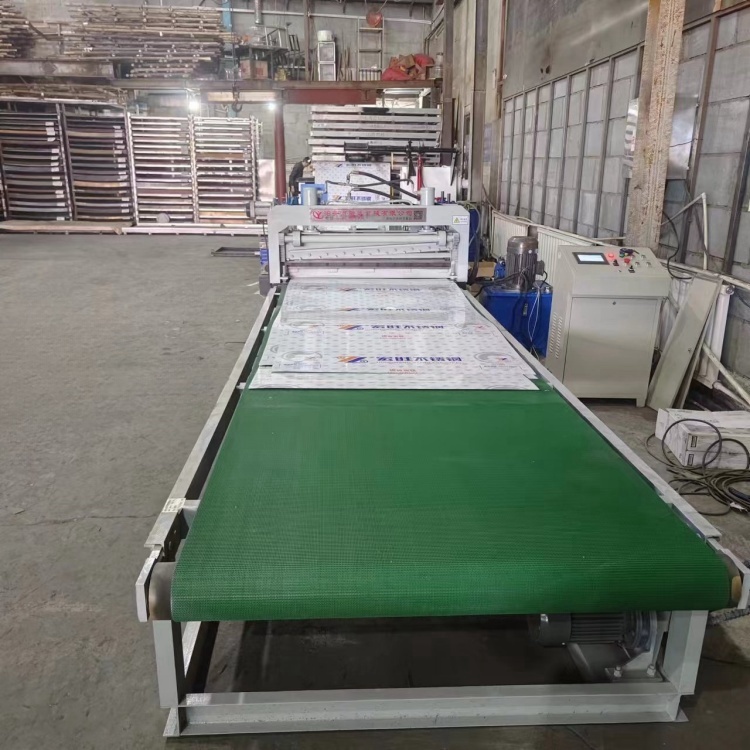

Hydraulic Unwinding Machine Fully Automatic CNC Leveling and Shearing Integrated Machine

Hydraulic uncoilers are used for automatic feeding of metal coil materials, which can better control the feeding accuracy and length, and have the function of automatic feeding and stopping.

The leveling and cutting machine can make the plates flatter, and the cutting length can be cut to size according to demand, with independent control.

Heavy duty levelling machine 16mm steel plate quadruple leveling machine

This leveling machine is specially designed for the metal plate sales manufacturers, with leveling function, easy to operate, leveling effect is very good. Whether for mass production or individual artisans, this equipment can improve work efficiency and ensure product quality, and is an indispensable tool in the metal processing industry. The use of this leveling machine can greatly save labor costs, improve production efficiency, ensure product quality, is the ideal choice for your metal processing plant.

Our factory produces various types of tile press, the main products are: Type 820, type 840, type 860, type 900, type 910, type 125 series tile presses; Kok Chi 750,1050 series tile pressLevelling and shearing machine;Hydraulic uncoiler;Hydraulic bending machine

Our factory produces various types of tile press, the main products are: Type 820, type 840, type 860, type 900, type 910, type 125 series tile presses; Kok Chi 750,1050 series tile pressLevelling and shearing machine;Hydraulic uncoiler;Hydraulic bending machine