Categories

Contact

E-mail :

chiyuan@chiyuanmachine.com

Phone/Wechat:

+86-15100871888

Address:

Botou Economic Development Zone, Cangzhou City, Hebei Province, China

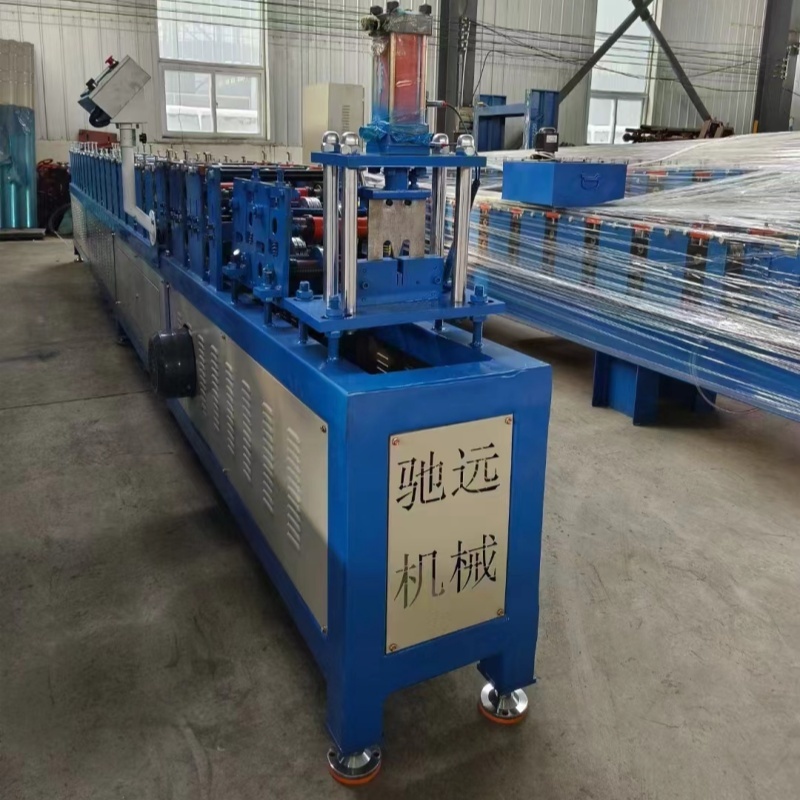

PRODUCT

Color steel tile machine metal wall panel roof tile forming machine efficient and convenient

The electric shearing machine is a widely used cutting device in machining, capable of cutting steel plates of various thicknesses and non-metallic materials, mainly used for flat cutting of irregular shapes.

Small, simple electric shears for metal

Electric shears are widely used shearing equipment in machining, capable of shearing steel plates and non-metallic materials of various thicknesses, mainly used for plane cutting of irregular shapes.

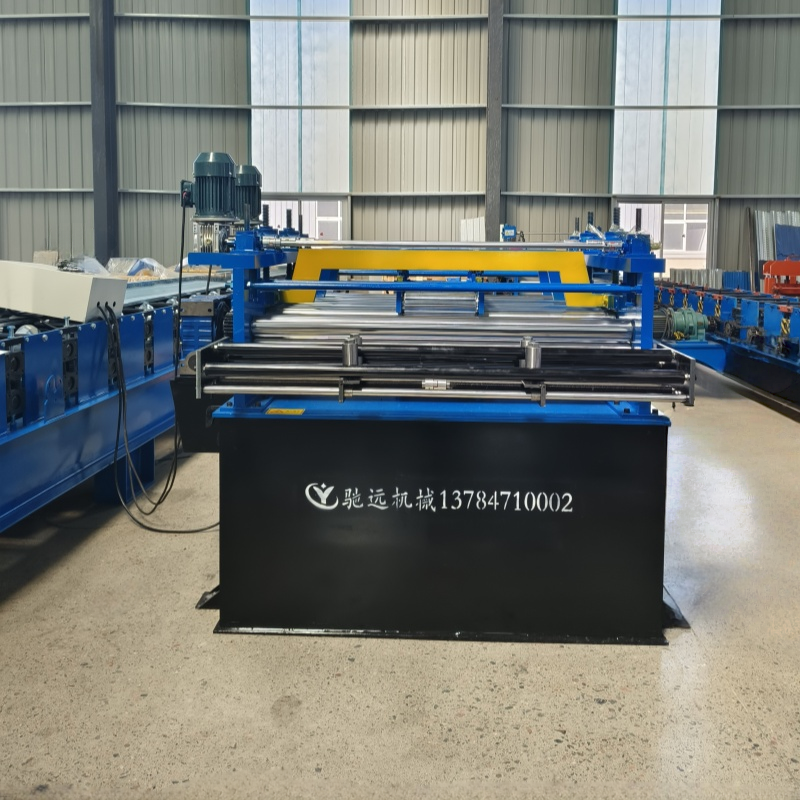

Metal material leveling machine, galvanized sheet, stainless steel sheet leveling equipment

The leveling machine is mainly used in the metal steel plate forming process, using the pressure of the upper and lower rollers to flatten uneven plates.

Applicable industries: Construction, building materials, manufacturing plants. Exhibition hall location: New. Condition: New. Material: Metal. Country of origin: China. Brand: Chi Yuan. Weight: 3600kg. Warranty period: 1 year. Automation level: Fully automated. Selling points: Simple operation, high safety performance, long service life, fully automatic rolling. Thickness: 0.3MM-1.2MM. Main equipment: Not specified. Width: 1300mm. Mechanical test report: Not specified. Factory inspection video: YES. Marketing type: Easy-to-operate and safe, hot-selling product. Core component warranty period: 1 year. Core components: Pump, motor, PLC, engine. Power: 5.5KW. Minimum order quantity: 1 set.

Color-coated steel sheets produced by roll forming machines are characterized by their smooth and beautiful appearance, uniform paint texture, high strength, and durability. They are widely used in industrial and civil buildings, such as factory buildings, warehouses, stadiums, exhibition halls, and theaters, for roofing and wall cladding. Color-coated steel tiles are easy to use and install, saving construction time and improving engineering efficiency. Combining different models of equipment into one machine saves floor space, and the cost of a roll forming machine is significantly lower than that of two single-layer machines.

The leveling machine is mainly used for metal sheet forming and processing, flattening uneven plates by the pressure of upper and lower rolls to achieve a flat effect on the material.

Hello, we are Chi Yuan Machinery, specializing in the production of purlin machines, hydraulic decoilers, leveling shear machines, various metal tile manufacturing machines, hydraulic shears, bending machines, and various metal cold bending forming equipment.

Our advantages lie in precise mechanical manufacturing, high efficiency, favorable equipment prices, aesthetically pleasing appearance, simple operation, and comprehensive after-sales service.

An uncoiler unwinds tightly wound metal coils into a smooth, continuous strip, providing a foundation for subsequent processing. This ensures product quality and processing precision on the production line. A leveler is mainly used in metal sheet forming processing, using the pressure of upper and lower rollers to flatten uneven sheets.