Innovative Solutions: Redefining Metal Fabrication with Hydraulic Bending Machines

May 01,2025

Innovative Solutions: Redefining Metal Fabrication with Hydraulic Bending Machines

Table of Contents

- 1. Introduction to Hydraulic Bending Machines

- 2. The Importance of Hydraulic Bending in Metal Fabrication

- 3. How Hydraulic Bending Machines Work

- 4. Advantages of Hydraulic Bending Machines

- 5. Applications of Hydraulic Bending Machines

- 6. Choosing the Right Hydraulic Bending Machine for Your Needs

- 7. Future Trends in Hydraulic Bending Technology

- 8. Conclusion

- 9. FAQs about Hydraulic Bending Machines

1. Introduction to Hydraulic Bending Machines

The world of metal fabrication is constantly evolving, and hydraulic bending machines are at the forefront of this transformation. These machines utilize hydraulic power to bend metal sheets and components with unparalleled precision and efficiency. As industries seek innovative solutions to improve productivity and quality, hydraulic bending machines have become indispensable tools in modern metal fabrication.

2. The Importance of Hydraulic Bending in Metal Fabrication

In the realm of metal fabrication, the ability to bend materials accurately is crucial. **Hydraulic bending machines** provide the necessary force to manipulate various metals into complex shapes and designs. This capability is essential for industries such as construction, automotive, and aerospace, where precision and reliability are non-negotiable. The importance of hydraulic bending lies in its ability to streamline production processes, reduce material waste, and improve overall product quality.

3. How Hydraulic Bending Machines Work

To understand the effectiveness of hydraulic bending machines, it's essential to grasp their operational principles. These machines operate using hydraulic fluid, which is pressurized to generate significant force. Here’s a breakdown of their functioning:

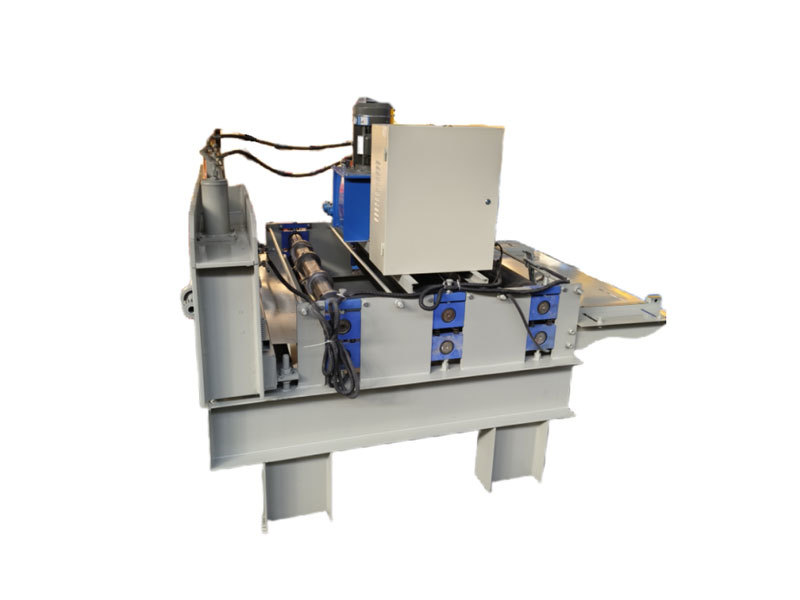

3.1 Components of Hydraulic Bending Machines

A typical hydraulic bending machine consists of several key components:

- **Hydraulic Pump**: Generates the hydraulic pressure needed for bending.

- **Cylinder**: Contains the hydraulic fluid and converts pressure into mechanical force.

- **Bending Tool**: The part that physically bends the metal.

- **Control System**: Allows operators to set parameters and control the bending process.

3.2 The Bending Process

The bending process starts when the operator selects the desired angle and specifications. The hydraulic pump then activates, pushing fluid into the cylinder and extending the ram. As the ram moves, it applies force to the bending tool, which bends the metal sheet according to the predefined angle. This process can be adjusted for different materials and thicknesses, making hydraulic bending machines extremely versatile.

4. Advantages of Hydraulic Bending Machines

Hydraulic bending machines offer several benefits that enhance metal fabrication processes:

4.1 Enhanced Precision

**Precision** is one of the standout features of hydraulic bending machines. The controlled application of force ensures that bends are consistent and accurate, significantly reducing the risk of error.

4.2 Increased Efficiency

With the ability to quickly adapt to various bending requirements, hydraulic machines minimize downtime and boost overall productivity. This efficiency translates into faster project completion times and reduced labor costs.

4.3 Flexibility in Bending Operations

Hydraulic bending machines can handle a wide range of materials, including stainless steel, aluminum, and copper. This versatility makes them suitable for various applications, from simple bends to intricate designs.

4.4 Reduced Material Waste

By achieving precise bends on the first attempt, these machines significantly cut down on scrap material, leading to cost savings and a more sustainable operation.

5. Applications of Hydraulic Bending Machines

Hydraulic bending machines are utilized across numerous industries, playing a critical role in various applications:

5.1 Automotive Industry

In automotive manufacturing, hydraulic bending machines are essential for creating complex components, such as frames and brackets, that require precise bends for structural integrity.

5.2 Aerospace Sector

The aerospace industry demands the highest standards of precision and quality. Hydraulic bending machines meet these requirements by producing lightweight yet strong components crucial for flight safety.

5.3 Construction

In construction, hydraulic bending machines are used to fabricate metal structures and reinforcements, allowing for quick assembly and enhanced durability.

5.4 Furniture Manufacturing

From chairs to tables, hydraulic bending machines help in creating stylish and functional furniture components, allowing designers to experiment with innovative designs.

6. Choosing the Right Hydraulic Bending Machine for Your Needs

Selecting the appropriate hydraulic bending machine is vital for optimizing your fabrication processes. Consider the following factors:

6.1 Assess Your Production Needs

Evaluate the volume and type of work you will be performing. High-volume operations may benefit from larger machines with advanced features, while smaller shops may opt for compact models.

6.2 Material Compatibility

Ensure the machine can handle the types of materials you will work with, including their thickness and hardness.

6.3 Control Features

Modern hydraulic bending machines offer various control options, including manual and CNC (computer numerical control) systems. CNC machines provide greater precision and automation, making them ideal for complex projects.

6.4 Budget Considerations

While investing in a high-quality hydraulic bending machine is essential, it’s crucial to stay within your budget. Consider long-term value and potential cost savings from improved efficiency and reduced waste.

7. Future Trends in Hydraulic Bending Technology

The landscape of hydraulic bending technology is continuously evolving. Here are some trends shaping the future of this industry:

7.1 Automation and Smart Technology

Automation is becoming increasingly prevalent in hydraulic bending processes. Smart machines equipped with sensors and data analytics can optimize performance and maintenance, leading to enhanced operational efficiency.

7.2 Eco-Friendly Innovations

As industries strive for sustainability, eco-friendly hydraulic bending machines that utilize less energy and produce less waste are gaining traction.

7.3 Integration with Other Technologies

The integration of hydraulic bending machines with other manufacturing technologies, such as laser cutting and welding, is enabling more streamlined and efficient fabrication processes.

8. Conclusion

Hydraulic bending machines are revolutionizing the metal fabrication landscape by offering innovative solutions that enhance efficiency, precision, and versatility. As industries continue to evolve, these machines will play an increasingly pivotal role in meeting the growing demand for high-quality fabricated products. Investing in the right hydraulic bending machine can lead to substantial benefits, including reduced waste, improved productivity, and the ability to tackle complex design challenges. Embracing these advancements will undoubtedly position manufacturers at the forefront of the industry.

9. FAQs about Hydraulic Bending Machines

1. What types of materials can hydraulic bending machines process?

Hydraulic bending machines can process a wide range of materials, including but not limited to aluminum, stainless steel, carbon steel, and copper.

2. How do I maintain a hydraulic bending machine?

Regular maintenance includes checking hydraulic fluid levels, inspecting hoses for leaks, and ensuring that the bending tools are sharp and in good condition.

3. What is the difference between a manual and a CNC hydraulic bending machine?

Manual machines require operators to control the bending process manually, while CNC machines are automated and use computer programming to achieve precise bends.

4. Can hydraulic bending machines handle thick materials?

Yes, hydraulic bending machines are designed to handle a variety of material thicknesses. However, the specific capacity depends on the machine model and specifications.

5. How can I improve the precision of my bending operations?

To improve precision, ensure that the machine is properly calibrated, use high-quality bending tools, and regularly maintain the equipment for optimal performance.

TAG:

PREVIOUS:

Contact Us

E-mail :

chiyuan@chiyuanmachine.com

Phone/Wechat:

+86-15100871888

Address:

Botou Economic Development Zone, Cangzhou City, Hebei Province, China