Understanding the Functionality and Benefits of Color Steel Tile Machines

Apr 22,2025

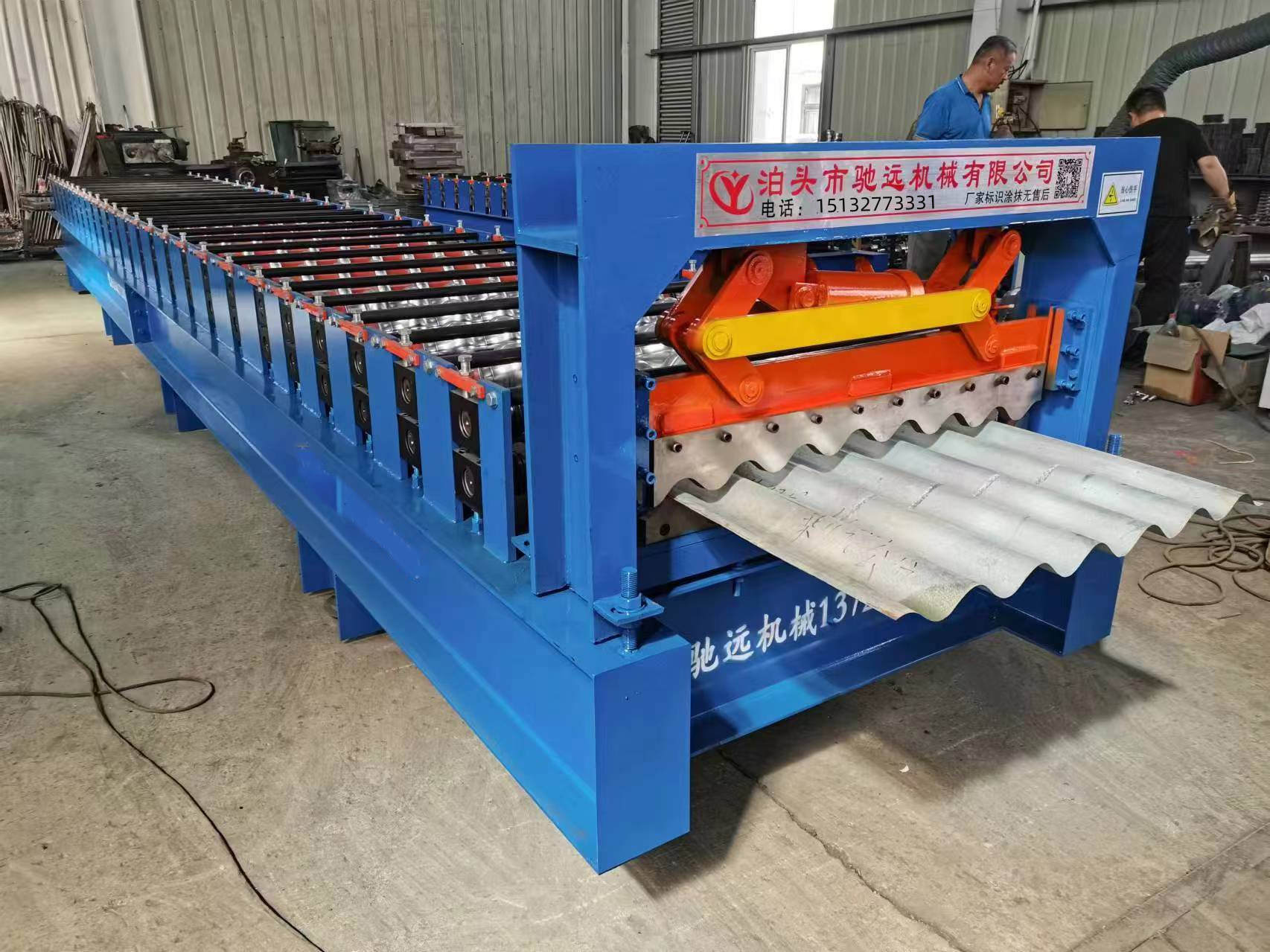

Color steel tile machines play a crucial role in the manufacturing processing machinery sector, specifically in the production of durable and aesthetically pleasing roofing materials. These machines are designed to create color-coated steel tiles that are widely used due to their strength, lightweight nature, and resistance to corrosion and environmental factors.

The primary function of a color steel tile machine is to convert raw steel coils into finished tiles through a series of processes, including uncoiling, forming, cutting, and surface treatment. The machine typically operates in several stages:

1. **Uncoiling**: The process begins with the uncoiling of color-coated steel sheets. These sheets are available in various colors and finishes, allowing for customization based on client preferences.

2. **Forming**: After uncoiling, the steel sheets are fed into a forming station where they are shaped into the desired tile profile. The design can vary significantly, depending on the architectural requirements and aesthetic demands of the project.

3. **Cutting**: Once the tiles are formed, they are cut to the required lengths. Precision in cutting is critical to ensure that each tile fits perfectly during installation and meets industry standards.

4. **Surface Treatment**: After cutting, tiles may undergo additional surface treatments to enhance their durability and visual appeal. This can include anti-corrosion coatings or finishing touches that improve weather resistance.

One of the significant advantages of utilizing color steel tile machines is their efficiency. These machines can operate at high speeds, producing a large volume of tiles within a short timeframe, which is essential for meeting market demands. Furthermore, the automation features integrated into modern machines reduce human error and minimize production costs, enhancing overall profitability.

Another benefit is the versatility of the end products. Color steel tiles are available in a myriad of colors and styles, making them suitable for various applications, from residential houses to commercial buildings. Their lightweight properties also ease the transportation and installation processes, further adding to their attractiveness as a roofing solution.

Additionally, the durability of color steel tiles contributes to their long service life, which is a significant consideration for any construction project. These tiles are resistant to fading, rust, and extreme weather conditions, ensuring that they maintain their appearance and functionality over time.

In summary, color steel tile machines are an essential investment for manufacturers in the processing machinery sector. By streamlining production and enhancing product quality, they not only meet the increasing demand for roofing materials but also contribute to sustainable building practices through their longevity and recyclability. Understanding the capabilities and advantages of these machines can significantly impact operational efficiency and product appeal in the competitive market.

The primary function of a color steel tile machine is to convert raw steel coils into finished tiles through a series of processes, including uncoiling, forming, cutting, and surface treatment. The machine typically operates in several stages:

1. **Uncoiling**: The process begins with the uncoiling of color-coated steel sheets. These sheets are available in various colors and finishes, allowing for customization based on client preferences.

2. **Forming**: After uncoiling, the steel sheets are fed into a forming station where they are shaped into the desired tile profile. The design can vary significantly, depending on the architectural requirements and aesthetic demands of the project.

3. **Cutting**: Once the tiles are formed, they are cut to the required lengths. Precision in cutting is critical to ensure that each tile fits perfectly during installation and meets industry standards.

4. **Surface Treatment**: After cutting, tiles may undergo additional surface treatments to enhance their durability and visual appeal. This can include anti-corrosion coatings or finishing touches that improve weather resistance.

One of the significant advantages of utilizing color steel tile machines is their efficiency. These machines can operate at high speeds, producing a large volume of tiles within a short timeframe, which is essential for meeting market demands. Furthermore, the automation features integrated into modern machines reduce human error and minimize production costs, enhancing overall profitability.

Another benefit is the versatility of the end products. Color steel tiles are available in a myriad of colors and styles, making them suitable for various applications, from residential houses to commercial buildings. Their lightweight properties also ease the transportation and installation processes, further adding to their attractiveness as a roofing solution.

Additionally, the durability of color steel tiles contributes to their long service life, which is a significant consideration for any construction project. These tiles are resistant to fading, rust, and extreme weather conditions, ensuring that they maintain their appearance and functionality over time.

In summary, color steel tile machines are an essential investment for manufacturers in the processing machinery sector. By streamlining production and enhancing product quality, they not only meet the increasing demand for roofing materials but also contribute to sustainable building practices through their longevity and recyclability. Understanding the capabilities and advantages of these machines can significantly impact operational efficiency and product appeal in the competitive market.

TAG:

Contact Us

E-mail :

chiyuan@chiyuanmachine.com

Phone/Wechat:

+86-15100871888

Address:

Botou Economic Development Zone, Cangzhou City, Hebei Province, China